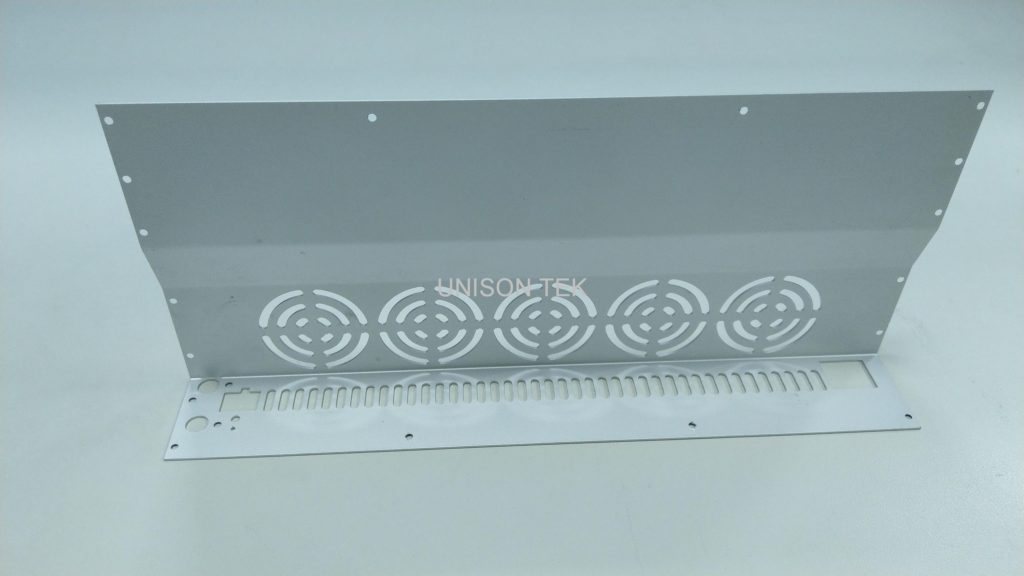

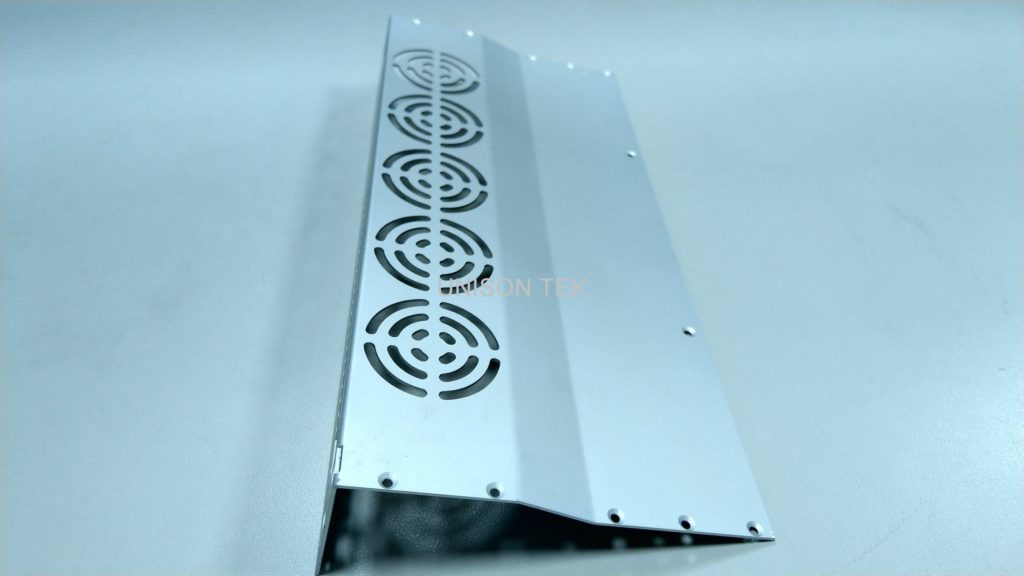

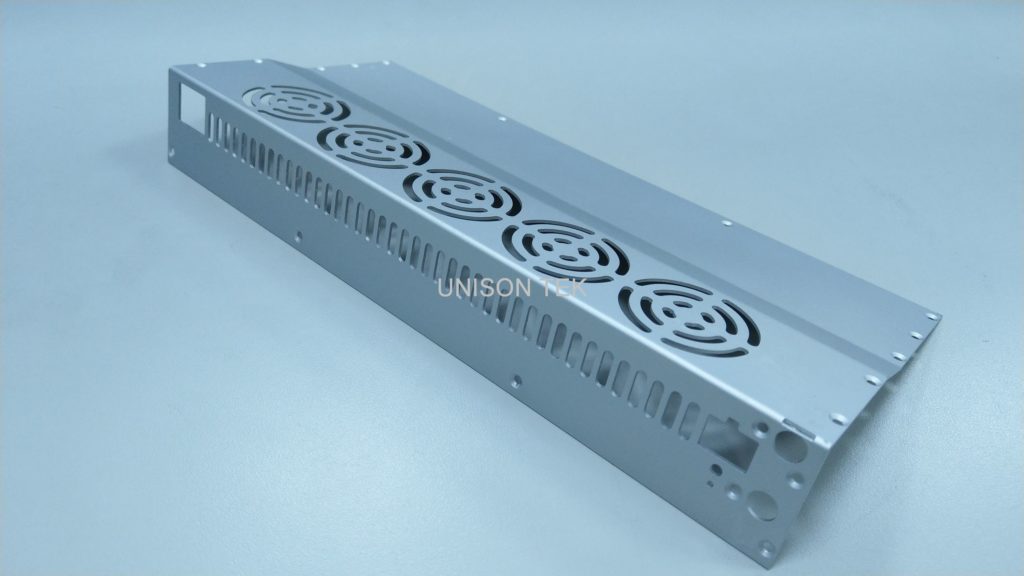

Stamping parts are provided by affiliates of Unison Tek with exceptional quality & competitive pricing. Sheet metal provided by Unison Tek are either made from stamping or laser cutting.

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser most commonly through optics.

We have the capability to make sure that your parts will be manufactured to your exact specifications and to the highest quality standards.

Tolerance Accuracy

Our tolerance accuracy can range between 0.10mm~0.05mm complying to your specs.

Materials

| Stamping | Laser Cutting |

| Aluminum | Aluminum |

| Brass | Brass |

| Stainless Steel | Stainless Steel |

| Plastic | Plastic |

Plating and Coating

| Metal Finish | Plastic Finish |

| Standard Minimal post processing are done upon request. | Standard Minimal post processing are done upon request. |

| For Aluminum Parts Anodizing thickness 12-15 µm. Hard Anodizing thickness above 40µm. Can be done with gloss & matt, provide samples to match for. | Glass-bead Blasting Surface is left with a smooth matt look. Abrasive particle size 100, 120 micron. |

| Glass-bead Blasting Surface is left with a smooth matt look. Abrasive particle size 100, 120 micron. | Custom Feel free to consult with us about other types of surface treatments if needed. |

| Custom Feel free to consult with us about other types of surface treatments if needed. |